Characteristics of End-of-Line Testing

Blog Post: End-of-line testing is much more than distinguishing between good and bad units

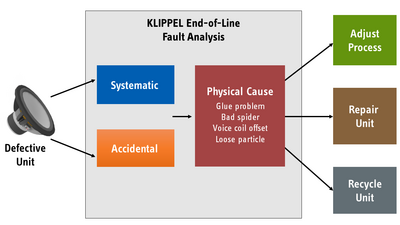

For manufacturers of audio equipment, such as speaker components, speaker units, and speaker systems, it is necessary to test the performance and sound quality of the final product in mass production to control the quality. EoL testing is much more than separating good from bad units. It is also about using the information contained in the defects to improve the design and optimize the production processes. That requires a detailed, sophisticated analysis that must be done using the latest insights in electro-acoustic, including nonlinear modeling, mechanical models, FEM, simulation and many more.

The physical causes of defective units reveal in many cases a potential way to avoid problems. Learning from existing failures and building a knowledge base significantly shorten the identification of similar problems in the future. This considerably eases actions to adjust the production process and invest money in development on the most relevant points. The QC System has a series of unique features, most of which are protected by patents and are not available in other testing systems.

We invite you to explore our blog series, where you will find a comprehensive list of these unique features and their applications in various fields. Alongside this, you will discover the relevant KLIPPEL QC product solutions.